CASE STUDY

Fighting PRRS and Lowering Disease Risk

for Sows at Mogler’s Pig Hill Farms

Implementing Visium Far-UVC reduces airborne risk and microbial load on farrowing surfaces

OVERVIEW

The Mogler family’s Pig Hill Farms West site is a critical hub of pig production within their breeding operation, housing the majority of their sows as well as gilt development and multiplication. As a key layer in the farm’s ever-evolving biosecurity and biocontainment strategy, Visium Far-UVC adds protection for the herd within the herd, functioning as an additional barrier alongside filtration to reduce the risk of airborne threats such as PRRS (Porcine Reproductive and Respiratory Syndrome).

Swine barns are particularly vulnerable to bioaerosols and airborne viruses like PRRS and Influenza, which can cause costly outbreaks even in filtered facilities. Located in Northwest Iowa’s densely pig-populated agricultural region, Pig Hill West faces unique biosecurity and biocontainment challenges.

THE CHALLENGE

Most on-farm biosecurity measures focus on contaminated surfaces (fomites) and entrypoint disinfection. Airborne pathogen intrusion strategies, however, only block a portion of external contaminants. Once a virus like PRRS enters a barn or infects a pig, reducing spread among animals becomes difficult. By integrating Far-UVC technology, incoming air receives an added layer of defense as bioaerosols can be rapidly inactivated, lowering risk for air transmission. Continuous operation also reduces overall surface bioburden, providing a novel level of biocontainment. By minimizing the microbial load within the barn, exhausted air carries fewer pathogens, helping to reduce risk of cross-contamination between facilities.

OUR SOLUTION:

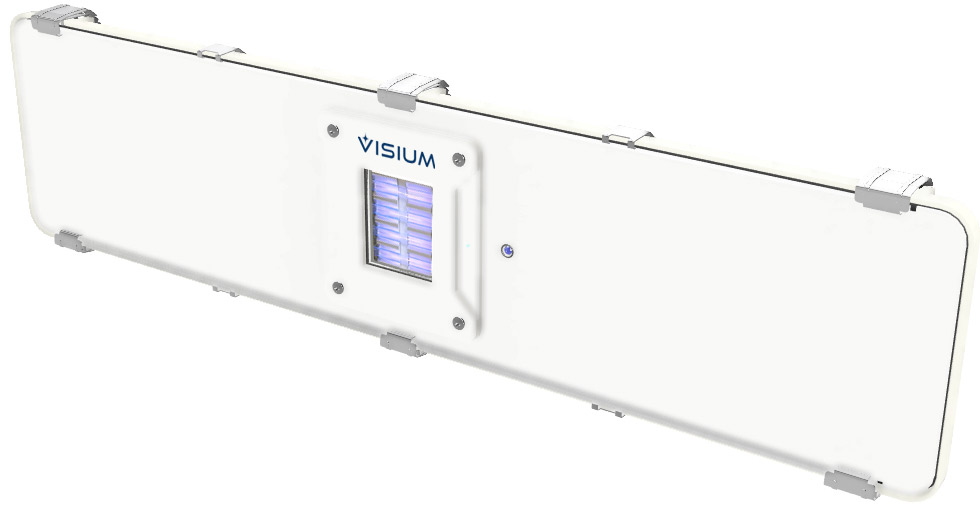

Visium Far-UVC Sealed Fixtures

Twenty-four Visium Sealed fixtures were installed in a farrowing room servicing 48 sows and their litters. The system provides continuous inactivation of airborne and surface pathogens across a 3,400 sq ft space. Fixtures were ceiling-mounted for seamless integration into the existing barn environment.

Third-Party Test Results

Independent testing was conducted by STERIXENE to assess the microbial impact of Visium Far- UVC.

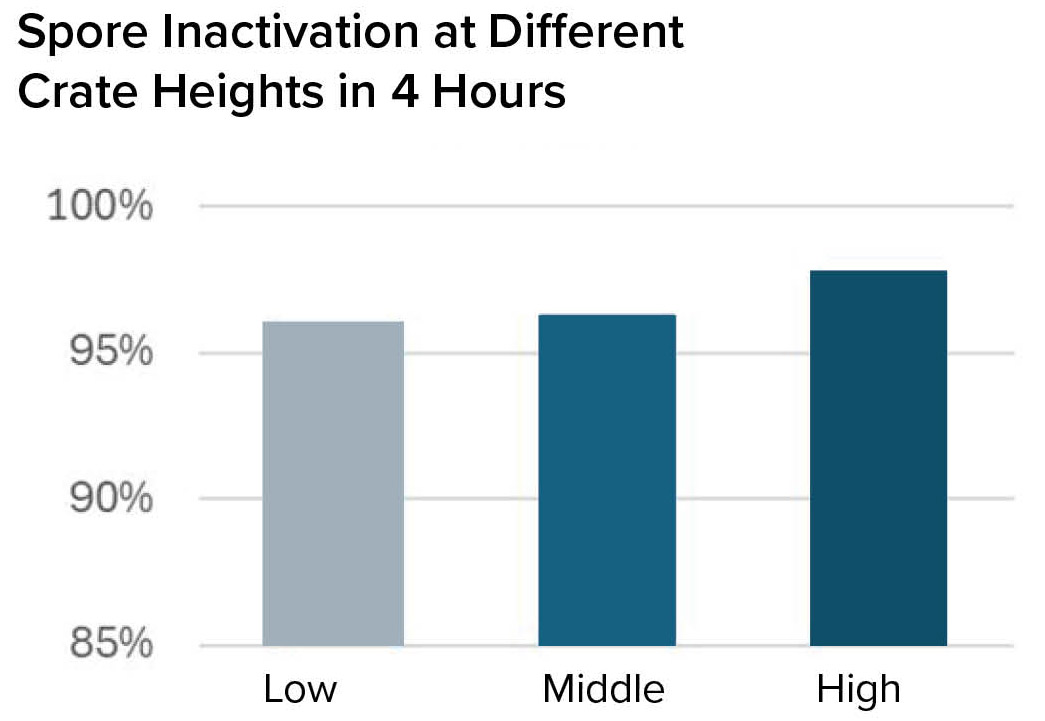

Surfaces close to the animals in the Visium equipped farrowing room were compared to untreated controls. Sealed bioindicator capsules containing highly resistant B. subtills spores were placed at representative locations across multiple surfaces.

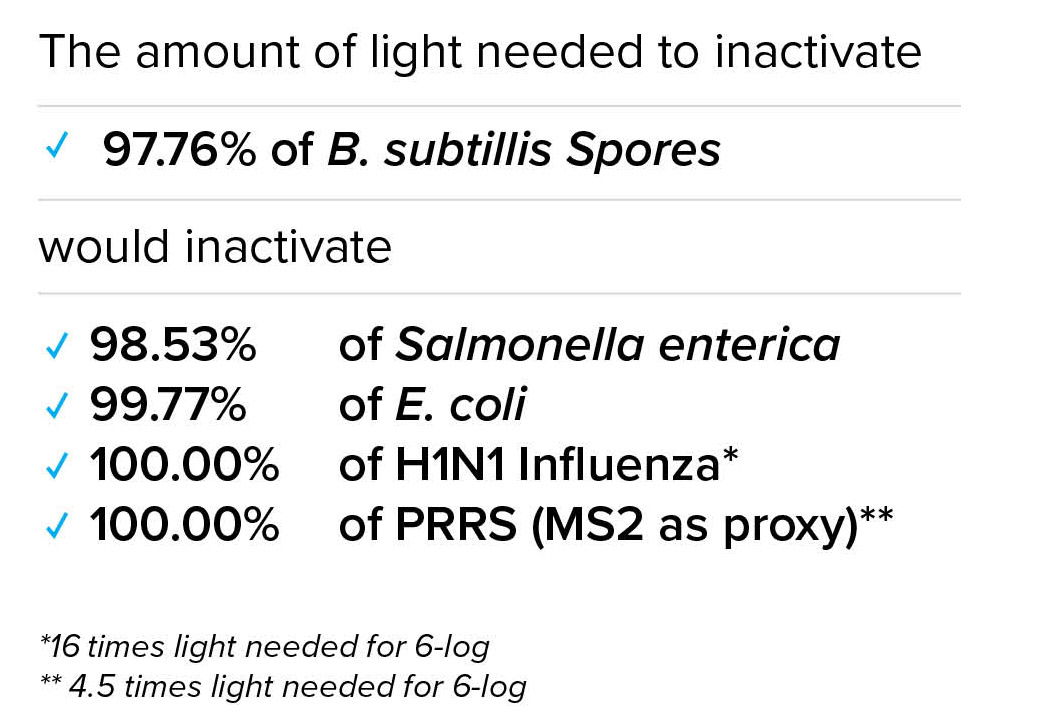

After four hours of continuous operation, results demonstrated that the Far-UVC output in the room was strong enough to inactivate 97.7% of spores, comparable to greater than 6-log reduction (99.9999%) of PRRS or of H1N1 Influenza.

Findings

Visium delivered a significant 97.7% reduction to hardy spores at animal level

Reduction was observed at every tested location, ensuring inactivation throughout the farrowing crate

“We are excited to learn more about Far-UVC and its opportunity to add another layer to our biosecurity front. We will continue to explore applications of advancing technologies and add tools such as Far-UVC to our box.”

Chet Mogler

Managing Partner – Swine Production

Pig Hill Farm

CONCLUSION

The Mogler family is dedicated to advancing animal welfare, sustainability, and disease prevention. With Visium Far-UVC, Pig Hill Farms strengthened its biosecurity infrastructure while improving air and surface quality without disrupting daily operations.

In four hours, Visium Far-UVC was able to inactivate the equivalent of 100% of PRRS, adding a layer of defense against airborne pathogens

Pig Hill Farms representatives view Visium as a next-generation biosecurity solution, a powerful safeguard against airborne pathogens and diseases like PRRS that threaten herd health and productivity.

Partner With Us

We are actively working with new facilities that want to understand what continuous sanitization can do in their own environment.

If your organization is exploring ways to improve indoor environmental quality and reduce pathogen risk, we welcome the opportunity to collaborate. Our team will assess your space, recommend an appropriate Visium solution, and support your deployment to help generate real world results tailored to your facility.