CASE STUDY

Performance Drone Works Operates the Cleanest Manufacturing Facility in the World with Visium

Visium Far-UVC fixtures continuously reduce airborne and surface pathogens in shared spaces

OVERVIEW

Performance Drone Works (PDW) is a defense technology company dedicated to strengthening America’s edge in unmanned aircraft systems. PDW develops secure, reliable solutions for military forces and public safety operations, giving frontline teams an exponential edge in speed, precision and resilience.

The company recently opened its new headquarters in Huntsville (“Rocket City”), Alabama. To maintain environmental integrity and reinforce operational resiliency, PDW partnered with Visium to integrate Far-UVC sanitization across shared and high-traffic spaces. With Visium, PDW operates the cleanest drone manufacturing environment in the world.

THE CHALLENGE

Shared spaces such as breakrooms, bathrooms, and conference rooms carry a constant risk of respiratory illness transmission. Bioaerosols linger in the air and microbes persist on high-touch surfaces between cleaning cycles. For a workforce that must operate in person and often in close proximity, even a single outbreak can disrupt production schedules, reduce workforce availability, and threaten mission-critical output. PDW needed a solution that provided continuous reduction of bioburden in the spaces where its people gather, supporting resiliency and uninterrupted operations.

OUR SOLUTION: Visium Far-UVC

PDW installed 38 Visium devices across its reception area, bathrooms, conference rooms, breakrooms and a community center, covering 6,826 sq ft of high-traffic space. The fixtures recess into the ceiling for seamless integration and continuously inactivate airborne and surface microbes while spaces are occupied.

KEY FEATURES

- Continuous 24/7 air and surface sanitization

- Far-UVC tech proven to reduce airborne pathogens

- Discreet and silent operation, for a patient-centered environment

- Visium app bridges IoT connectivity for real-time monitoring via mobile devices

INDEPENDENT TEST RESULTS

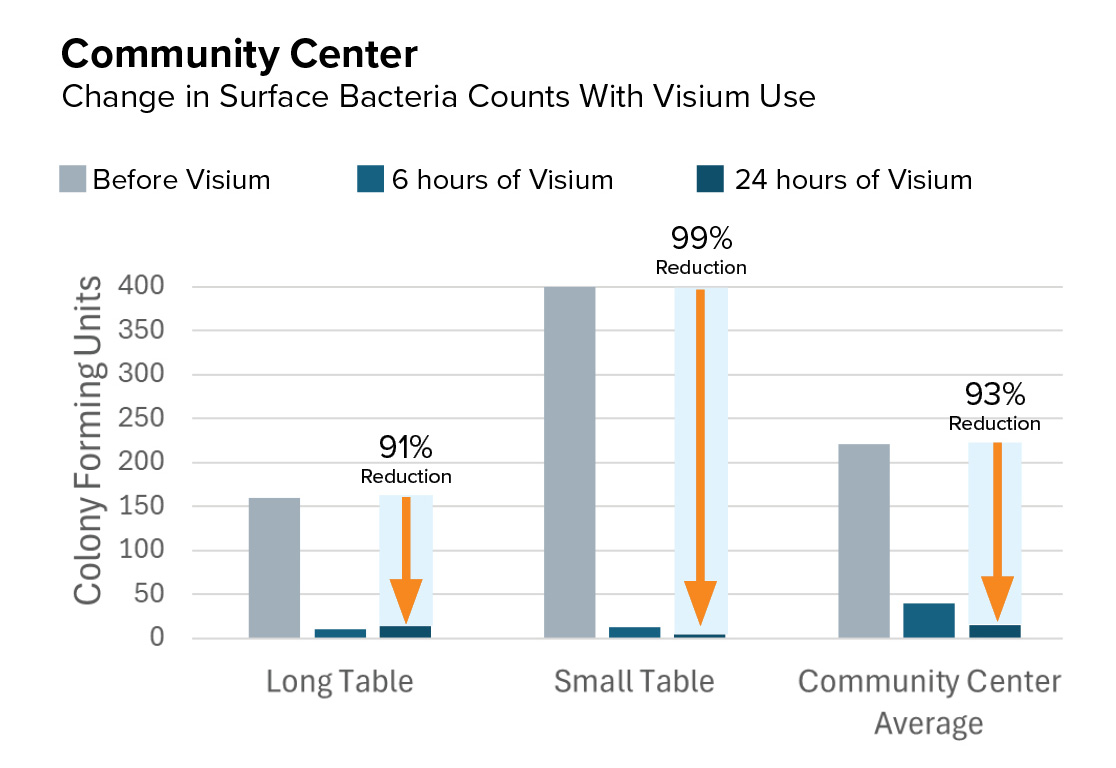

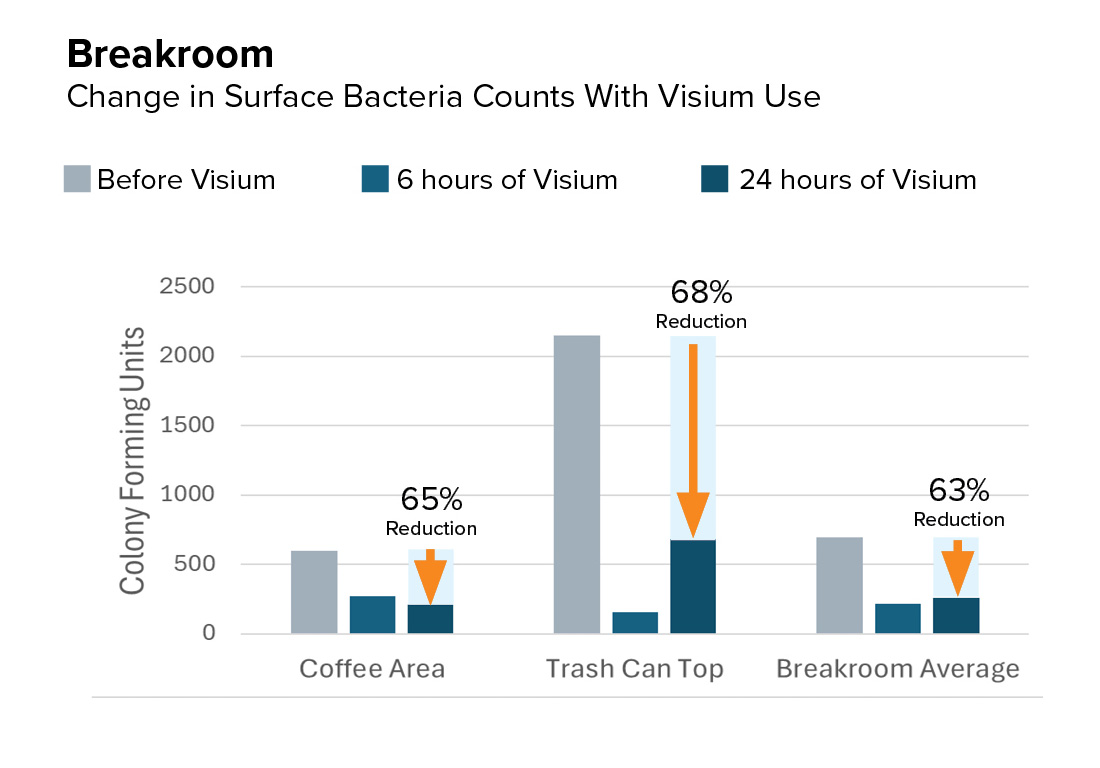

Testing by US Micro Solutions validated the impact of continuous Far-UVC sanitization:

Up to 99% reduction in colony-forming units (CFUs)

A 69% reduction of CFUs in the Breakroom within 6 hours

An average of 82% reduction of CFUs in the Community Center within 6 hours

A new, lower baseline of bioburden established after 24 hours

OUTCOMES

Visium transforms PDW’s facility into a workplace combining advanced manufacturing with environmental safety.

Independent analysis confirms consistent bacterial reduction

Visium reduces CFUs by up to 99%, even in high-use areas

Continuous operation maintains a lower baseline of surface contamination

Cleaner shared spaces support workforce resiliency

“Drone Factory 01 was built to set a new benchmark for scale, speed, and reliability in defense manufacturing. Part of that responsibility is creating the safest and cleanest environment possible for the people who make it happen. By installing Visium Far-UVC, we are reinforcing that commitment. It is another way we are delivering ahead of the threat, both for our customers and for our team.”

Preston Taylor

Senior Director, Business Operations

CONCLUSION

PDW demonstrates that advancing national defense includes maintaining the integrity of indoor environments where its workforce operates. By adopting Visium Far-UVC, the company ensures its new headquarters is the cleanest drone manufacturing facility in the world. This sets a benchmark where innovation in defense manufacturing and environmental safety advance together.